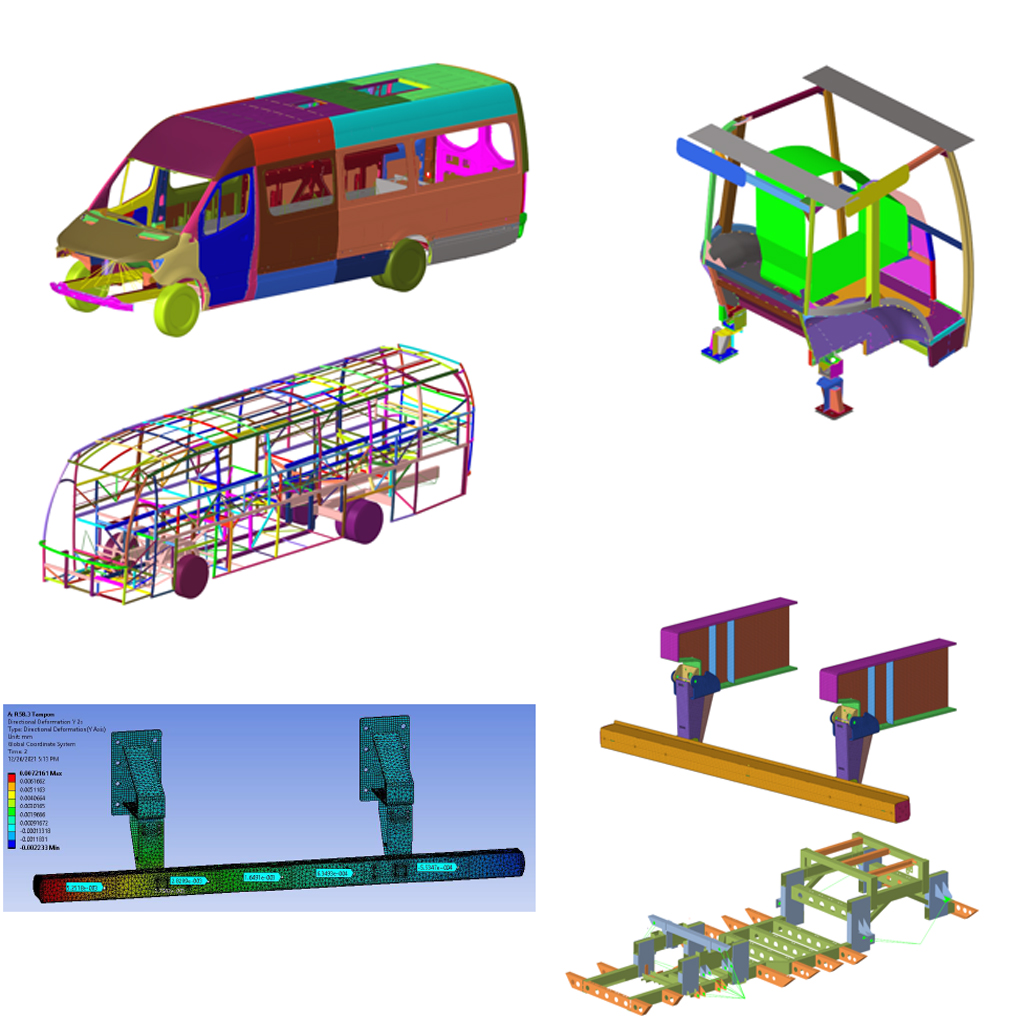

Simulation

- FE Model Services

Finite element method (FEM) is the process of separating a physical problem into small components called finite elements in order to solve it by analysis method. IAS provide services in the preparation of FE Models.

- Static Durability and Strength Analysis

Structural durability and strength analysis are preferred in determining and optimizing high stresses and deformations that may occur in the structure under certain load conditions.

- ECE R66 Rollover Analysis

Rollover analysis are analysis in which the superstructure strength of M2, M3, ClassII, ClassIII and Class B vehicles with more than 16 passengers is examined according to the ECE R66 regulation.

In principle, it is based on the fact that the vehicle rolls over from a height of 800mm to the side that is considered to be in bad condition and that the vehicle superstructure does not violate the residual space defined by the regulation during this rollover.

- ECE R58 Rear Underrun Protective Device (RUPD) Analysis

Rear Underrun Protection Device (RUPD) are structures fitted on heavy commercial vehicles and their trailers to prevent other road users from getting under the vehicle in rear-end crash accidents.

- EU 1005/2010 Towing Device Analysis

Compressive and tractive tests for towing device according to Regulation EU 1005/2010

- EU 1322/2014 ROPS and FOPS Analysis

According to the EU 1322/2014 Regulation, the following tests are carried out for the safety of drivers in the cabins of construction machines and agricultural vehicles.

- Rollover Protective Structure(ROPS) and

- Falling Object Protective Structure(FOPS)

- Validation Services

In computer-aided analysis (CAE), the mathematical model must be validated against actual test conditions. For this reason, the validation process is carried out as seen in the flow chart below.

Questions? You’re Covered

We are determined to provide you with detailed and accurate simulation results.

Automotive simulation is a computer-based modeling and simulation method used to test and analyze vehicle design, performance, safety, and other factors in a virtual environment. This accelerates the prototype development process and reduces costs.

The advantages of automotive simulations include cost savings, accelerated development processes, reliable safety and performance testing, reduced need for physical prototypes, and the ability to analyze environmental impacts.

Common software used for automotive simulations includes ANSYS, MATLAB/Simulink, ADAMS, CarSim, and LS-DYNA. These programs are used to conduct various tests and analyses.

Automotive simulations are used in areas such as vehicle dynamics, crash testing, fuel efficiency, aerodynamic analysis, thermal management, acoustic analysis, and testing of electric vehicle components.